High Precision Hot Forgings, Forging Metal Parts According to Drawings

Product Description: Hot forging is a metalworking process in which metals are plastically deformed above their recrysta

Send your inquiryDESCRIPTION

Basic Info.

| Surface Treatment | Hot Galvanized |

| Forging Tolerance | +/-0.5mm |

| Standard | AISI |

| Certification | ISO 9001:2008 |

| Trade Assurance | Protect Your Order Everything |

| Applied Software | PRO/E,Auto CAD,Solid Work ,Caxa |

| Quality | High Level |

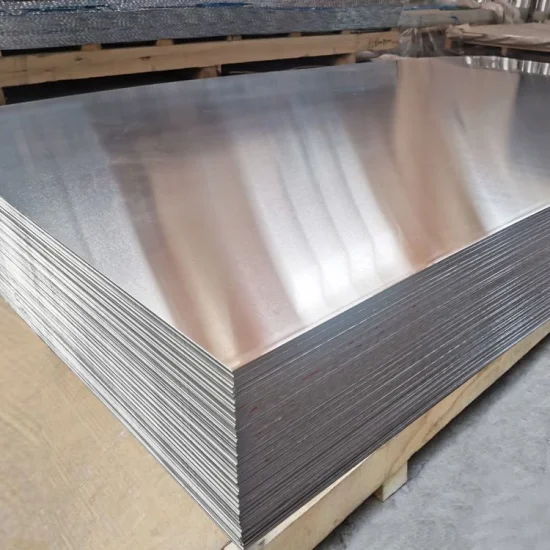

| Item | Custom Homemade Metal Stamping Parts |

| R&D | 3 Engineers for Electric Gold Plated Stamping Part |

| Port | Qingdao/Shanghai/Guangzhou |

| Surface Finished | Sandblasting, Painting, Polishing, Poweder Coating |

| Sales Team | Response Within 24 Hours |

| Inspection | 100% Factory Inspection in House |

| Warranty | We Borne 100% Responsibility for Quality Problem |

| OEM Experiences | 13years |

| Sample | for Free |

| Delivery | 15-20working Days |

| Experience | Since 2006 |

| Certificate Available | ISO,SGS,Certification of Raw Materials,Normal Cust |

| Transport Package | Wooden Box/Cartons/as Your Need |

| Specification | OEM ODM parts |

| Trademark | YX |

| Origin | Shandong, China |

| HS Code | 84621010 |

| Production Capacity | According to The Customer′s Needs and Arrange |

Product Description

Product Description:

Hot forging is a metalworking process in which metals are plastically deformed above their recrystallization temperature, which allows the material to retain its deformed shape as it cools. Hot forging is accomplished using hydraulic or pneumatic hammers, presses, and other similar machinery that are used to compress the heated metal into its desired part shape. This is most often achieved using a custom die. The dies used in hot forging are custom-made to match the customer's part designs. Because hot metal is more pliable, this process allows for more intricate shapes than cold forging, making a vast array of part geometries possible. However, tolerances used in hot forging are generally not as tight as in cold forging.Hot forging begins with a forged metal ingot or a cast metal piece. The work stock is heated until it reaches its plastic deformation temperature (recrystallization temperature), which must be maintained throughout the hot forging process. Depending on the material, this temperature can be as high as 1200°C. As the material is formed and shaped, its grain structure is broken down and homogenized into finer grains, which increases the yield strength, ductility, and toughness of the material.After the hot forging process ends, parts must be cooled rapidly to "set" the metal in its new shape. Care must be taken in the cooling process, however, as cooling hot forged parts too quickly can result in warping. Additionally, the hot forging process produces little to no material scrap, making it one of the most efficient fabrication methods available.

Product Specifications: | |

| Material: | Aluminum, A380, A356, ADC12, AlSi10Mg, 104, 102 etc. |

| Dimension: | According to the drawing or sample |

| Standard: | DIN GB ISO JIS BA ANSI |

| Casting equipment: | 80T/160T/250T/300T/500Tcasting machine,Sand blasting machine,5T electri stove,Metallographic detector,Independent mould manufacturing |

| Production Process: | Polish/Sand Blast/EDM/Milling/Texture/Grind/Pre-Treatment/Quenching/Lathe/Wire Cut/Annealing/Temper etc. |

| Equipment of Casting: | 1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T2. Gravity casting machine: 5 production lines3. Low pressure die casting machining: 1 production line4. Sand casting machine: 6 production lines5. Degassing equipment and opportunities to refine the material6. Machining: 5Sets CNC Machines;3 sets Milling machines; 3 setsTurning machines; 10 sets drill and tap machines |

Hot Forging Characteristics

Hot forgings can be divided into forgings with and without flash. Flash is necessary to produce complex 3D geometries with very different local cross-sections and secondary design elements. The flash acts as a brake on the material flow and slows the flow of excess material. Thus, high internal pressure is built up in the die, which forces the remaining material into the die cavities.Flashless forgings are generally limited to axisymmetric components or components with cyclic-symmetric geometries.Hot die forgings are usually manufactured in multiple steps. Semi-finished rolled products (round or rectangular sections) are used as blanks. In rare cases, continuous-cast material or profiled semi-finished products can be used.

Hot Forging Materials

Hot forging can be used to fabricate a broad spectrum of parts, and can be performed with most metal materials, including:Carbon steelAluminumTitaniumCopperNickel alloys

Hot Forged Product Applications

Our outsourcing hot forging offshore partners can create custom parts that match your design specifications. Sun Fast can deliver hot forgings in a wide variety of sizes and metal options. The strength and durability of hot forged parts makes them ideal for more rugged applications, some of which include:Automotive manufacturingAgricultureTools and hardwareAerospaceConstruction equipmentAnd moreBecause every hot forging we provide is custom-made, the design possibilities are all but limitless.Hot Forging Advantages & Disadvantages

Hot forging of metals as a fabrication technique has been around for centuries. Through the process mechanical properties of the metal that is being forged are improved through the metal's grain structure, which makes it tougher and stronger. Hot forging can be utilized with almost any metal and can be used to fabricate a wide range of parts. There are numerous advantages that hot forging can provide over cold heading. Some of the more common advantages and disadvantages of hot forging, include:Advantages Good ductilityExcellent surface qualityIncreased flexibilityGood for custom partsDisadvantagesTolerances are less dimensionally preciseCooling process must be carefully monitoredWarpage possibilitiesIncreased monetary costsRisk of atmosphere reactions

Why choices us?

- In China, we have more than 13 years of experience in processing foreign companies for foreign companies.

- China manufacturer in Qingdao,not trade company

- Competitive price and nice service

- ISO/SGS passed

- Application: Automotive,medical device, electronics, toy, furniture, industrial etc.

Our Products:

1. auto parts, classic car parts2. machine parts, pump body housing, engine parts, cylinders, pistons, transmission housing.3. cookware parts, kitchen ware parts.4. medical equipment parts, housing, instrument housing, I beam, housing...etc. 5. Bicycle and motocycle parts, sport equipment parts, housings, covers, heat sinks.

Our Policy:

Innovation and developing in TechniqueHigh level of expertiseOutstanding quality

On-time delivery to customer needs

PACKAGE:

Transport:

Related Products