Nimonic90 / Gh90 / Uns No7090 / Age

Overview Nimonic90 / Gh90 / Uns No7090 / Age-Strengthened Cobalt-Nickel-Based Wrought Superalloy Product Description Nim

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | Nimonic90 |

| Mean Coeff Thermal Expansion | 9.17 |

| Elongation | 25% |

| Tensile | 1035MPa |

| Melting Point | 1320-1365c |

| Diameter | 6~100mm |

| Density | 8.19 G/Cm |

| Transport Package | Wooden Case |

| Specification | Customized |

| Trademark | DLX |

| Origin | Jiangsu, China |

| HS Code | 7505120000 |

| Production Capacity | 1500tons/Year |

Product Description

Nimonic90 / Gh90 / Uns No7090 / Age-Strengthened Cobalt-Nickel-Based Wrought SuperalloyProduct Description

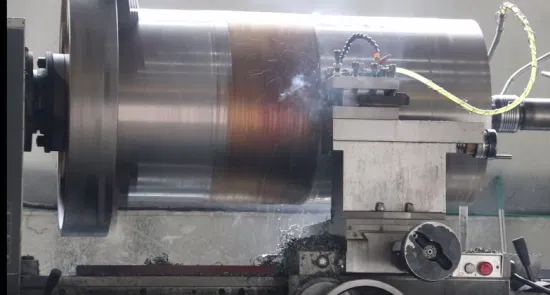

Nimonic90Nimonic 90 is a precipitation-hardenable nickel-chromium-cobalt alloy having high stress-rupture strength and creep resistance at temperatures to about 1700°F (920°C). Nimonic 90 also has good resistance to high-temperature corrosion and oxidation. Nimonic 90 is used for blades and discs in gas turbines, hot-working tools, and springs.

Available forms of Nimonic 90 are round, flats, extruded section, plate, sheet, strip, tube, and wire.

Nimonic alloy 90 is a precipitation hardenable nickel-chromium-cobalt alloy strengthened by the addition of Titanium and Aluminium. Alloy 90 has a high stress rupture strength and creep-resistant at temperatures to 920°C. Nimonic Alloy 90 is typically used in extreme stress applications such as turbine blades, hot working tools, exhaust reheaters, disc and high-temperature springs.The recommended heat treatments for Nimonic 90 are as follows:Nimonic 90 BarSolution Treatment - 1080 °C (1975 °F) for 8 hours + air cool or oil/ water quenchPrecipitation Heat Treatment (As per BS HR2) - 700 °C (1290 °F) for 16 hours + air coolNimonic 90 SheetSolution Treatment - 1100-1150 °C for 1-10 minutes + air cool or oil /water quenchStabilization Heat Treatment - 925 °C for 1 hour + air coolPrecipitation Heat Treatment - 750 °C for 4 hours and air cool(BS HR202/ MSRR 7016 / Siemens TLV 85252100 do not require the Stabilization Treatment stage)

| Chemical Composition Limits | ||||||||||||||

| Weight % | Ni | Cr | Co | Ti | Al | C | Si | Cu | Fe | Mn | B | S | Zr | Pb |

| Alloy 90 | Bal | 18-21 | 15-21 | 2-3 | 1-2 | 0.2 max | 1.0 max | 0.2 max | 1.5 max | 1.0 max | 0.02 max | 0.015 max | 0.15 max | 0.0020 max |

Typical Mechanical Properties

| MaterialExtruded Bar | Temperature °C | Yield Strength 0.2 % (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness HV |

| Nimonic 90 barSolution Treated (BS HR2) | RT | - | - | - | 295 max |

| Nimonic 90 barPrecipition Treated (BS HR2) | RT | 695 min | 1080 min | 20 min | 310 min |

| Nimonic 90 BarPrecipitation Treated (BS HR2) | 500 | 672 (typical) | 1038 (typical) | 31 | - |

| MaterialSheet | Temperature °C | Yield Strength 0.2 % (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness HV |

| Nimonic 90 sheetSolution Treated (BS HR202) | RT | - | - | - | 250 max |

| Nimonic 90 sheetPrecipitation Treated(BS HR202) | RT | 695 min | 1080 min | 25 min(0.45mm-3.0mm) | 280 min |

| Nimonic 90 sheetPrecipitation Treated(BS HR 202) | 500 | 740 (typical) | 995 (typical) | 30 | - |

| Alloy 90 Cold Rolled Sheet(Heat Treated) |

AvailabilityNimonic Alloy 90 (Nimonic 90) is available in sheet, strip, plate, bar, round bar, flat bar, wire, forging stock, tube, welding wire and extruded section. For all stock availability contact Sales.

SpecificationsUNS N07090Werkstoff Nr. 2.4632Werkstoff Br. 2.4969NiCr20Co18TiNCK20TA (AIR 9165)BS HR2AMS 5829MSRR 7137, MSRR 7017

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our Advantages

What is your working time?

Monday-Friday : 8:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls e-mail us during our holiday if u have any questions.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 15 days after payment has been confirmed.